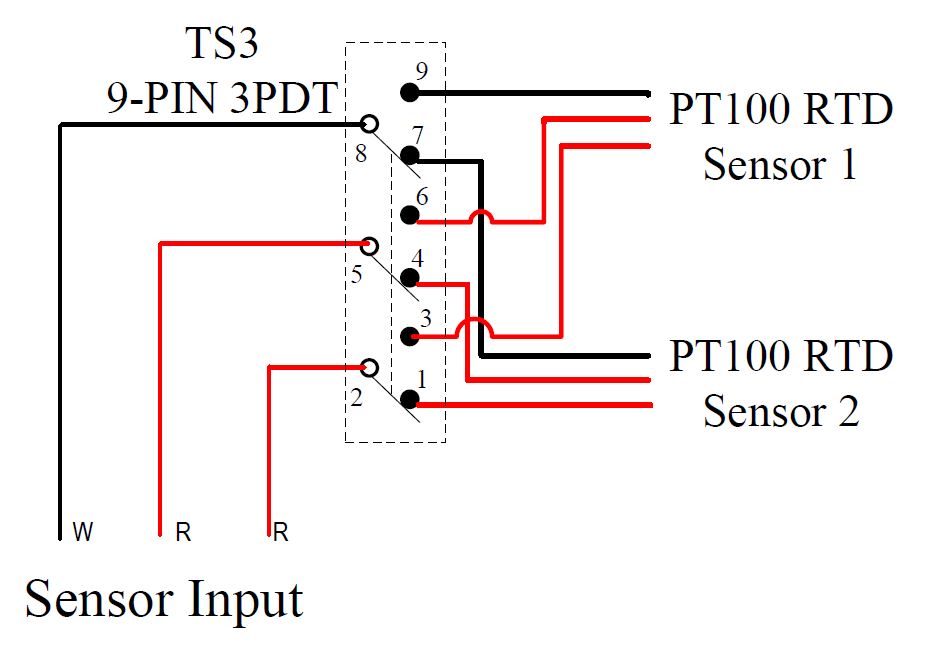

The best configuration for a specific application depends on a number of factors however the sensor configuration must match with transmitter otherwise leadwire resistance cancellation circuitry. Eo is the output voltage.

Pt100 Rtd Colour Codes Iec 60751

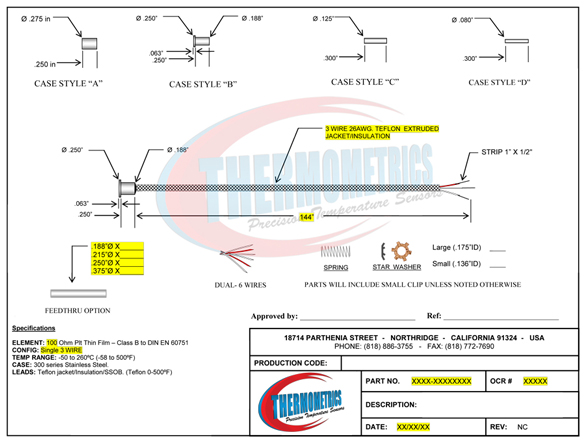

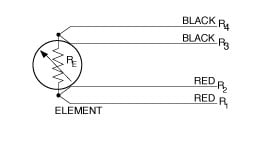

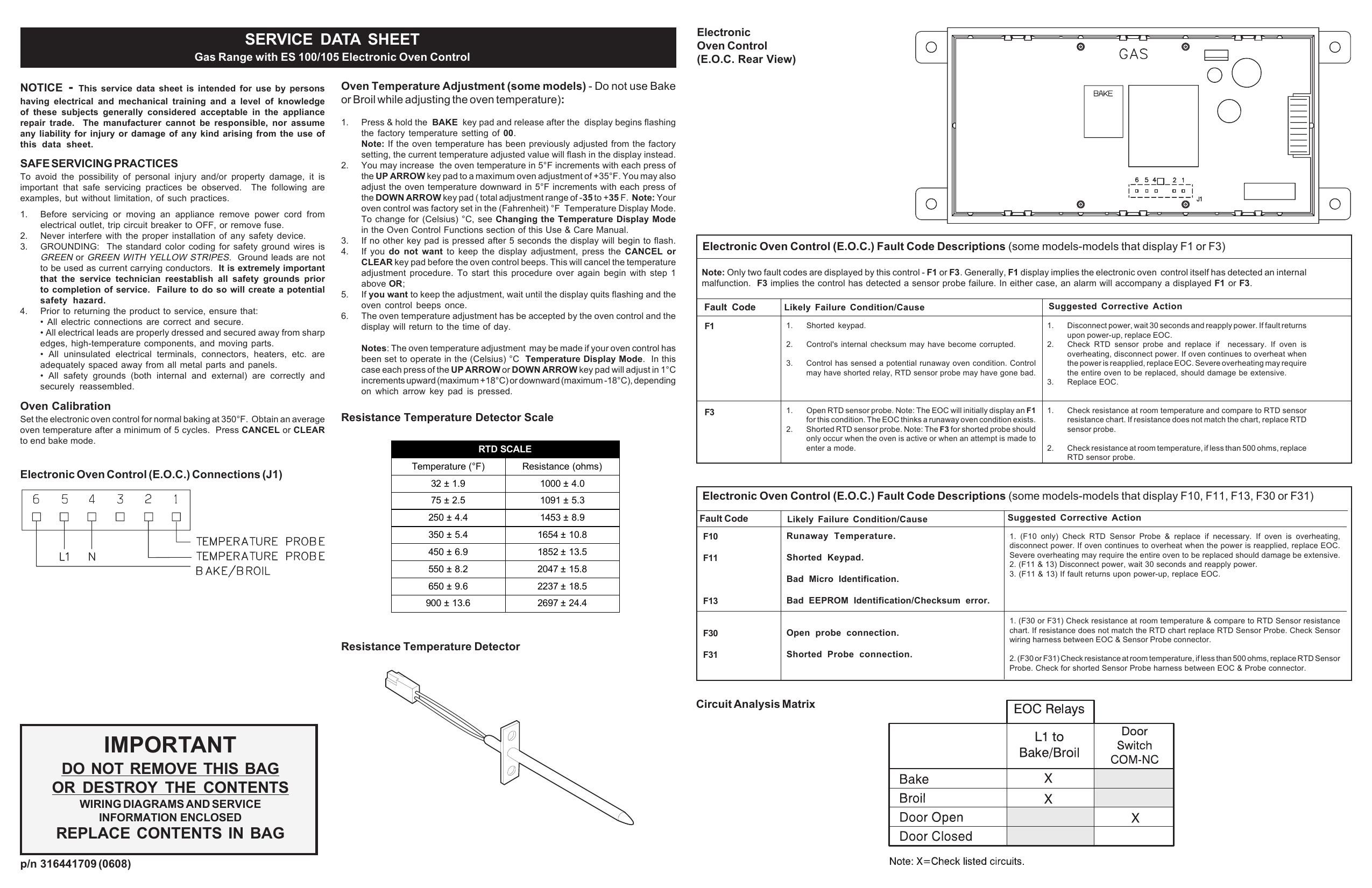

Rtd sensor wiring diagram. Difference between 2 wire rtd 3 wire rtd and 4 wire rtds rtds resistance temperature detectors are offered with 2 3 or 4 lead configuration. Es is the supply voltage. There are 2 wiring methods for the rtd module and pt100 temperature sensors two wire and three wire connections. 4 wire rtd signal connection connect each of the red leads on the positive side of the resistive element to the excitation positive and channel positive on the daq device. Rtd technical data see also. 3 wire rtd connections the 3 wire rtd configuration is the most commonly used rtd circuit design and can be seen in industrial process and monitoring applications.

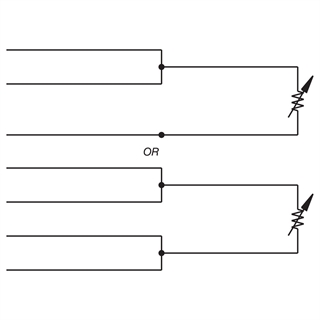

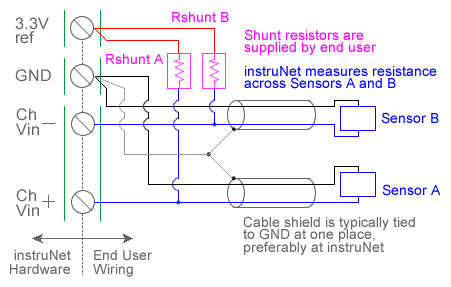

The resistance increases as the temperature of the sensor increases. An rtd is a passive device. The following connection diagrams illustrate how to connect various rtd types to your daq device. In this uncompensated circuit lead resistance l1 and l2 add. It does not produce an output on its own. When wiring with two wires first jumper across a1 and b1and a2 and b2 respectively then connect pt100 sensors and to the rtd module according to the following diagram on the left.

Wellborn assortment of rtd pt100 3 wire wiring diagram. A wiring diagram is a streamlined standard photographic depiction of an electrical circuit. Then either solder closed the jumpers next to the rtd terminal block or put little wires in the right and left terminal blocks to short them together. A 2 wire rtd configuration is the most useful with high resistance sensors or in applications where a great deal of accuracy is not required. The resistance vs temperature relationship is well known and is repeatable over time. Normally a 2 wire rtd will lose accuracy due to the resistance in the cable which can be thousands of feet long.

This is the easiest wiring you can just use either terminal block slot on the sides for each wire. In this article the possible wiring alternatives for rtd probes are explained. R1 r2 and r3 are fixed resistors. An rtd resistance temperature detector is a sensor whose resistance changes as its temperature changes. Sensors using the 3 wire construction are the most common design found in industrial process and monitoring applications. And rt is the rtd.

The lead wire resistance is factored out as long as all of the lead wires have the same resistance. June 17 2019 by larry a. The 3 wire rtd uses 1 additional wire and the 4 wire rtd uses 2 additional wires to compensate for the wire resistance. Shown is a 2 wire rtd connected to a typical wheatstone bridge circuit. Connect the black or white lead on the negative side for the resistive. A1b1 a2b2 and c1c2.

Generally speaking field devices have inputs for 3 wire sensors to. It shows the components of the circuit as streamlined shapes and also the power and also signal links between the gadgets. Otherwise errors can result.